Introduction: The Timeless Allure of Tamahagane

Tamahagane, a traditional Japanese steel, is celebrated for its extraordinary quality and historical significance. Forged through an intricate process involving iron sand and charcoal in a clay furnace called a tatara, it embodies craftsmanship honed over centuries. This steel’s uniform composition and high carbon content make it ideal for creating blades that balance sharpness, resilience, and flexibility. Its production, rooted deeply in Japanese culture, requires precise control of temperature and meticulous refinement.

Swordsmiths regard tamahagane not merely as a material but as a vessel of artistry and tradition. Its distinct properties continue to captivate experts seeking unparalleled perfection.

The Origins of Tamahagane: A Deep-Rooted Tradition

Tamahagane, meaning "jewel steel" in Japanese, holds a history intertwined with the cultural and metallurgical heritage of Japan. Its origins are traced back to the Heian period (794–1185), where the development of traditional steelmaking supported the creation of legendary samurai swords. This steel is derived through the tatara smelting process, an ancient method utilizing iron sand (satetsu) and charcoal.

During smelting, skilled artisans manage furnace temperatures and airflow meticulously over several days. This process results in distinct layers of high-carbon steel and slag, which are later separated by evaluation of texture and spark patterns. The refined tamahagane enables unparalleled sharpness, flexibility, and durability in swords, symbolizing mastery and resilience.

The Unique Composition of Tamahagane Steel

Tamahagane steel's distinctiveness lies in its exceptional purity and unique carbon composition. Crafted from iron sand, or satetsu, it is refined through the traditional tatara smelting process. This labor-intensive method melts and solidifies the iron over three days, producing steel with varying carbon levels.

The steel is then carefully sorted into two primary grades:

- High-carbon steel (kera), prized for its hardness, ideal for sharp edge formation.

- Low-carbon steel, valued for its flexibility, ensuring a strong yet resilient blade core.

The fusion of these types allows swordsmiths to achieve the perfect balance of durability and sharpness, a hallmark of Japanese blades.

The Intricate Process of Tamahagane Production

Tamahagane, a traditional Japanese steel, is renowned for its meticulous production process. It begins with iron sand, specifically satetsu, sourced from select regions in Japan, which is rich in iron content. This sand is heated in a tatara furnace over several days to extract usable steel.

Skilled artisans carefully regulate the temperature and airflow to ensure the steel achieves its desired quality. The impure layers of slag separate during high temperatures, leaving behind refined steel. Quality assessment is then performed, and the steel is categorized by carbon content, ensuring only the finest material is used for smithing swords.

Why Tamahagane is Ideal for Swordsmithing

Tamahagane stands as a preferred material for swordsmithing due to its unique properties. This high-carbon steel, produced using traditional Tatara smelting methods, offers exceptional purity and balance between hardness and flexibility. Skilled artisans value these characteristics for crafting blades that maintain a sharp edge while resisting brittleness.

Key Features That Make Tamahagane Superior

- Purity: It minimizes impurities, ensuring a clean structure.

- Carbon Content: Balanced levels optimize performance.

- Layering Potential: Ideal for Damascus-style forging.

Its ability to withstand intricate processes like folding and layering further solidifies Tamahagane as the ultimate choice for traditional swordsmiths.

Tamahagane vs. Modern Steel: A Comparison

Tamahagane, a traditional Japanese steel, is characterized by its purity and unique composition, derived from smelting iron sand in a tatara furnace. Unlike modern steel, it contains uneven carbon distribution, which swordsmiths exploit to achieve the perfect balance of hardness and flexibility. Modern steel, produced using advanced industrial methods, offers standardized compositions and uniformity, making it ideal for consistent manufacturing. However, it often lacks the historical authenticity and artistic allure that Tamahagane embodies. While modern steel prioritizes strength and cost-effectiveness, Tamahagane emphasizes craftsmanship and cultural symbolism. This distinct variance highlights different priorities in martial and artistic applications.

Master Swordsmiths and Their Bond with Tamahagane

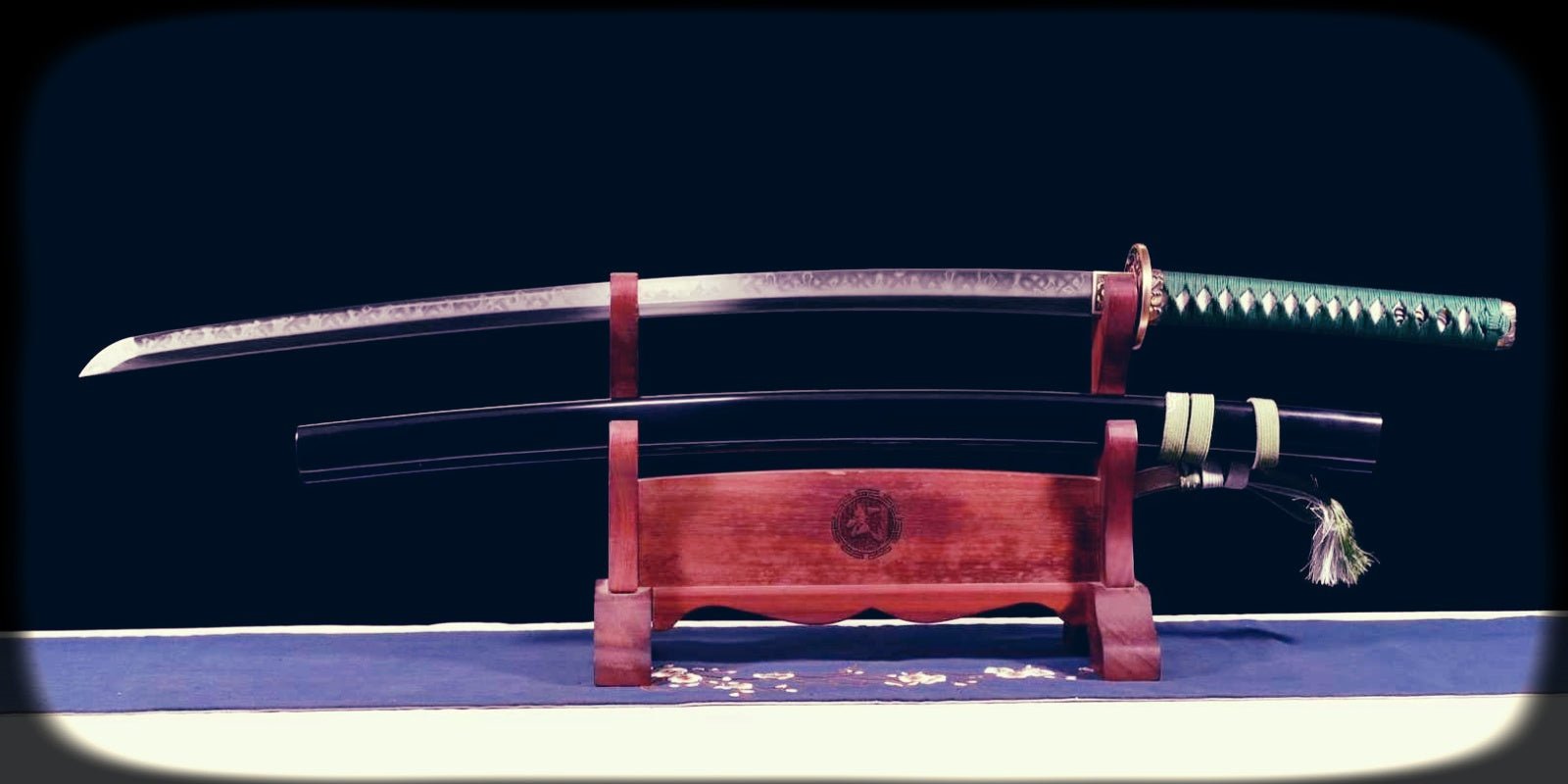

Master swordsmiths possess a profound connection to tamahagane, the traditional Japanese steel revered for its unmatched purity and strength. This bond is cultivated through centuries-old processes that demand skill, patience, and reverence. Tamahagane’s unique composition, forged from iron sand and charcoal in a tatara furnace, embodies the perfect balance of hardness and flexibility—essential for crafting resilient katana blades.

Swordsmiths meticulously inspect tamahagane, selecting only the finest fragments for forging. Through repetitive heating, folding, and hammering, they draw out impurities while achieving optimal structural alignment. This process transforms raw steel into an exquisite blade, preserving both functionality and artistry, a hallmark of Japanese sword-making traditions.

The Role of Tamahagane in Japanese Sword Culture

Tamahagane, derived from iron sand through traditional smelting processes, holds a revered position in Japanese sword culture due to its spiritual and functional significance. As the primary material for crafting katana and other iconic blades, it embodies the fusion of craftsmanship and cultural heritage. Swordsmiths value its unique carbon distribution, which enables the blade to achieve both sharpness and flexibility—qualities central to samurai warfare philosophy.

The intricate process of refining Tamahagane mirrors the dedication integral to Japan’s sword-making traditions. It is more than a material; it symbolizes centuries-old techniques, connecting modern smiths to ancestral artistry and the values it represents.

Modern Applications and Relevance of Tamahagane

Tamahagane, renowned for its purity and unique structure, continues to hold significant relevance in modern applications. While historically linked to Japanese swords, artisans today utilize this steel in crafting kitchen knives, high-end tools, and decorative pieces. Its fine-grained properties grant superior sharpness and durability, making it ideal for precision work.

Swordsmiths and metalworkers prioritize Tamahagane for its ability to yield aesthetically striking patterns through folding techniques. Modern enthusiasts and collectors appreciate the steel’s connection to cultural heritage and craftsmanship. Furthermore, its limited production ensures authenticity, sparking global demand for artists, historians, and high-performance tool users alike.

The Preservation of Traditional Tamahagane Crafting

Tamahagane, a steel renowned for its purity and resilience, is forged using methods refined over centuries by Japanese artisans. It is produced through the tatara smelting process, where iron sand and charcoal are combined under precise conditions. This labor-intensive method creates a steel with exceptional structure and integrity, a hallmark that modern machinery struggles to replicate. Efforts to preserve this tradition go beyond craftsmanship—they encompass cultural values, historical continuity, and a dedication to excellence. Through the mentorship of apprentices and government support, traditional swordsmithing thrives, ensuring the legacy of Tamahagane crafting remains unbroken for future generations.

Ethical and Sustainable Practices in Tamahagane Production

The modern production of tamahagane has increasingly prioritized ethical and sustainable practices, reflecting a growing awareness of environmental and cultural responsibilities. Efforts are made to ensure the iron sand, or satetsu, used in its creation is responsibly sourced, minimizing ecological disruption in the extraction process.

Smelting operations are conducted with careful attention to pollution control, reducing carbon emissions by employing traditional methods that rely on renewable resources like charcoal rather than fossil fuels.

Respect for the cultural significance of tamahagane also plays a key role. Producers often collaborate with local smithing communities to uphold ancestral techniques while supporting fair labor conditions.

Conclusion: The Enduring Excellence of Tamahagane in Swordsmithing

Tamahagane stands as a paragon of traditional craftsmanship, blending ancient techniques with metallurgical precision. Its unique structure, featuring high carbon pockets interspersed with lower carbon regions, allows swordsmiths to achieve an extraordinary balance of hardness and flexibility. The labor-intensive tatara smelting process ensures unparalleled purity, making it the ideal foundation for legendary blades like the Japanese katana. Moreover, its ability to retain a sharp, enduring edge while maintaining resilience under stress elevates its utility. Swordsmiths, guided by centuries of honed expertise, continue to trust Tamahagane for achieving both artistic mastery and functional superiority in their work.